Business divisions

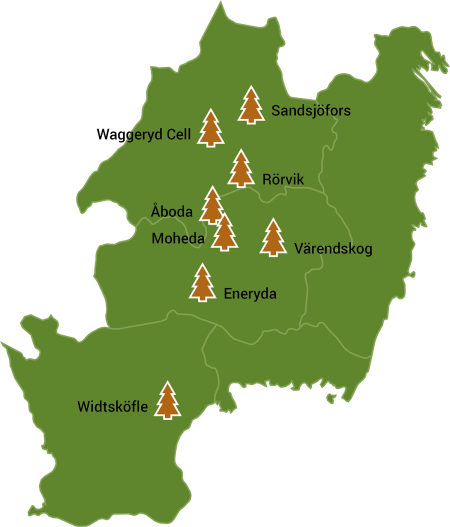

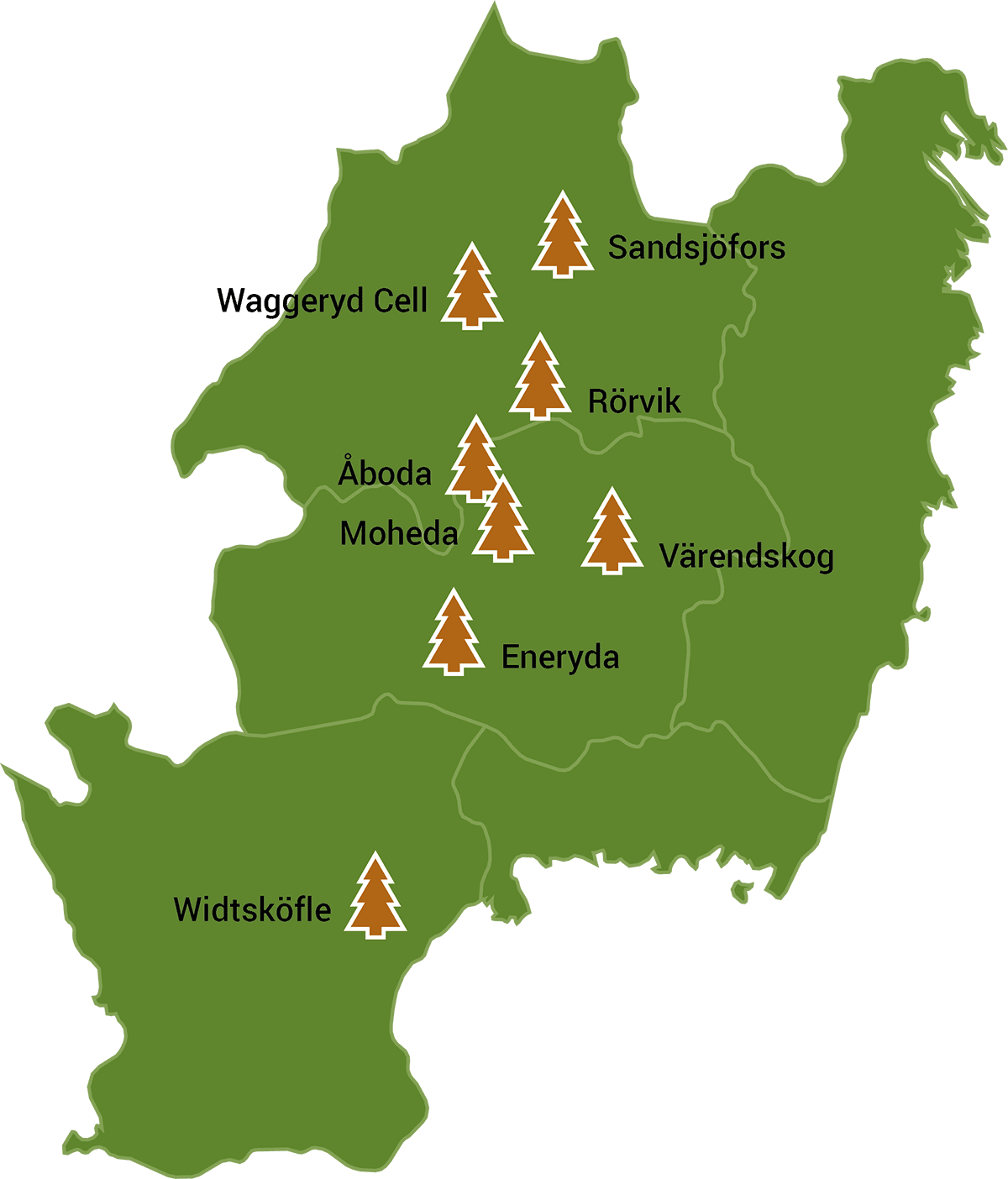

The business divisions cover four separate areas: processing of sawn timber, production of BCTMP pulp as well as raw material purchasing and forestry services. The production units are strategically located in southern Sweden, with seven saw lines, eight planing lines, seven batch kilns and 36 chamber kilns sited at six modern and effective saw mills.

In addition, ATA Timber fully owns and operates Waggeryd Cell, a state-of-the art pulp production mill, as well as ATA Timber Värendskog, a company that purchases raw material and provide forestry services in southern Sweden. Forest regeneration is vital to preserve sustainability in the Swedish forests. ATA Timber facilitates extensive planting of approximately 3 000 000 saplings annually.

Together the sawmills produce about 520 000 m3 of sawn wood products annually, of which 80-85% is exported globally. The pulp production capacity is approximately 225 000 tonnes per year and 85% of the final product is exported. Guaranteeing sustainability is the main priority in every aspect of the production process.

Together the sawmills produce about 520 000 m3 of sawn wood products annually, of which 80-85% is exported globally.

Sandsjöfors

In November 2017, the ATA Group’s new world-class saw line opened at the Sandsjöfors plant

Phone +46 382-78 68 00

Rörvik

ATA Timber R-vik saws standard timber from spruce and pine with an annual production of 90 000 m3 sawn timber.

Phone +46 382-57 70 10

Värendskog

Värendskog is a forest management and purchasing company that has been operating for over 30 years.

Åboda

The Åboda sawmill is the ATA Group’s first mill, established in the 60’s. Annual production is about 60 000 m3 of sawn timber.

Phone +46 472-36100

Moheda

The Moheda mill is the largest sawmill facility in the Group. Annual production is about 60 000 m3 of sawn timber.

Phone +46 472-36100

Eneryda

ATA Timber Eneryda AB is engaged in sawing low-grade timber. Auuual production is about 60 000 m3 of sawn timber.

Telefon +46 476-221 38

Widtsköfle

Normal-grade timber is sawn at ATA Timber Widtskövle. Annual production is about 75 000 m3 of sawn timber.

Telefon +46 44-35 03 00